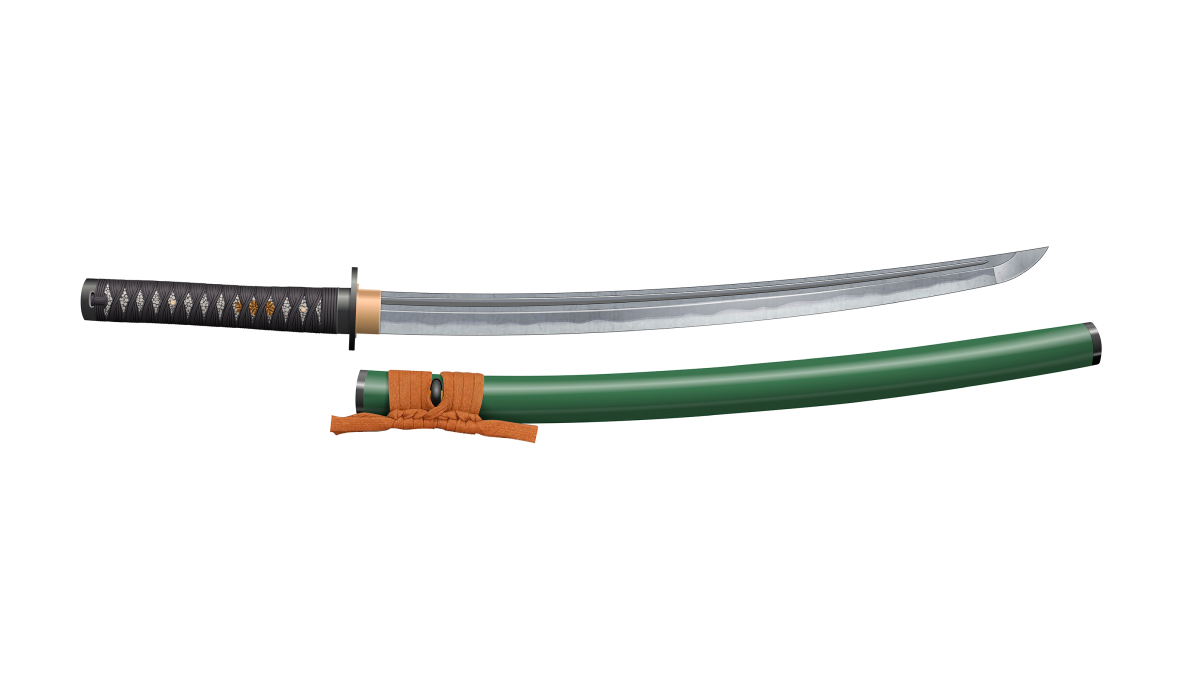

Blade

Handle/Fittings

Scabbard & Extras

Steel Type

When choosing a sword, the type of steel is crucial depending on your intended use. Some steels are renowned for their durability or edge retention, while others have attractive patterns that are better suited for display rather than practical or combat use. To help you make the best choice, we've added detailed descriptions for each type of steel.

The 1045 High Carbon Steel has a 0.45% carbon content in its blade. This steel is relatively soft and easy to work with, resulting in it being more affordable. When properly heat-treated and quenched 1045 Carbon swords can be a battle-ready option for light-cutting practice targets, ideal for beginners.

The 9260 spring steel, with 0.60% carbon and 2% silicon, creates a flexible and sturdy blade that can easily bend without breaking. Its rust resistance makes it ideal for both decorative and heavy-duty cutting tasks.

1095 High Carbon Steel has a carbon content of 0.95%. The high carbon content makes it very sturdy and durable, and heat treatment gives it the right level of flexibility. This balance makes it one of the most popular blades due to its excellent affordability-to-durability ratio.

T8 steel is a modern industrial tool steel known for its durability and strength. Renowned for toughness, T8 excels in cutting tasks against hard targets like bamboo or tatami mats. It is also the most affordable tool steel, making it a popular choice.

Damascus steel is made by pattern-welding two different metals together into one. It is ideal for decorative purposes, especially when polished. However, when properly heat-treated, it can also function as a real battle-ready sword.

The S5 Steel is known in the sword community as "shock steel" due to its ability to retain a sharp edge after rigorous and prolonged cutting activities. Essentially, it's one of the best materials for making durable swords that holds edge well.

The main difference between S5 and S7 tool steel lies in their hardness. S5 can be more manageable during heat treatment, which makes it slightly superior.

Wootz steel, also known as traditional Damascus steel, is made by melting iron, steel, and other elements with charcoal in a closed crucible. This process results in a blade with exceptional hardness and a distinctive pattern. Wootz steel swords are rare and highly prized by collectors.

Similar to Wootz Steel, Crucible Steel blades also have unique patterns, but their hada (surface pattern) is more delicate and finely divided than that of Wootz Steel.

LD Steel is a modern, battle-ready tool steel highly valued in the sword community. Difficult to produce, it is exceptionally rare. Known for its toughness, flexibility, and ability to retain a sharp edge without cracking after heavy cutting tests.

The ZXN-275J is a modern spring steel ideal for abusive tameshigiri (cutting tasks) against hard targets like bamboo or tatami mats. It is a marvel of blade material with the right balance of hardness, toughness, and the ability to bend without breaking. This custom modern steel was created by the Shadow Dancer team and cannot be found anywhere else